ISO 9001QMS Corrective Action Request Template ISO Templates and Documents Download

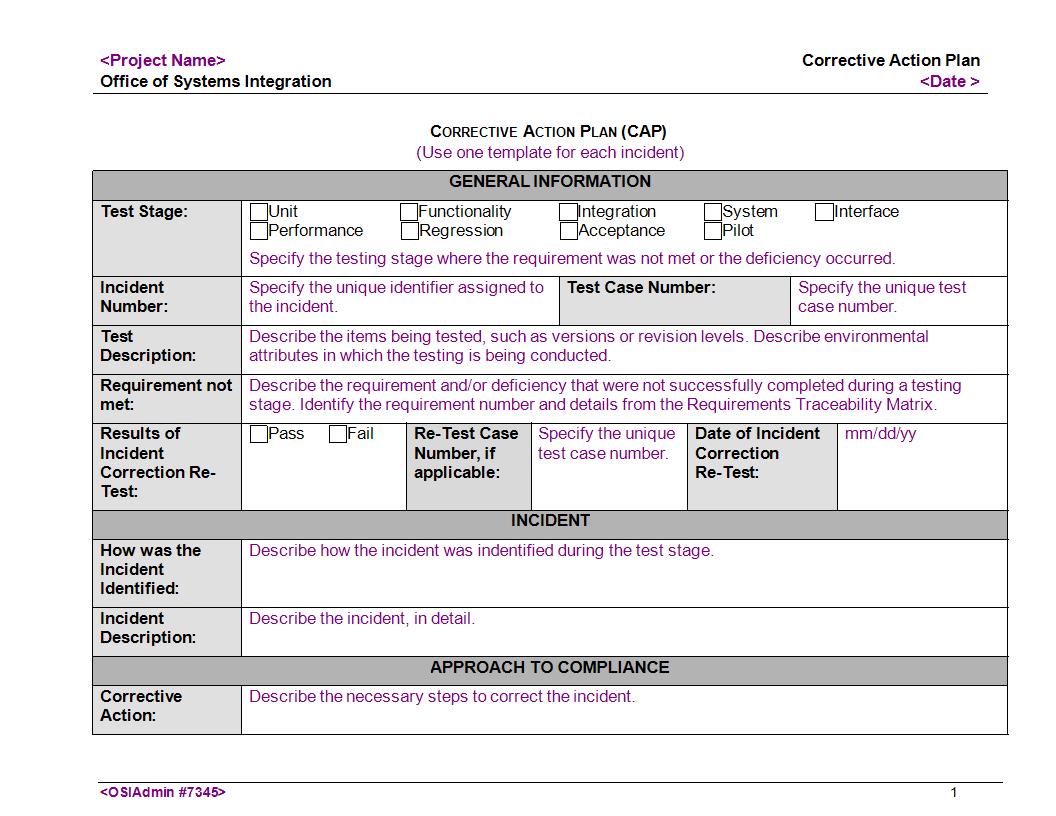

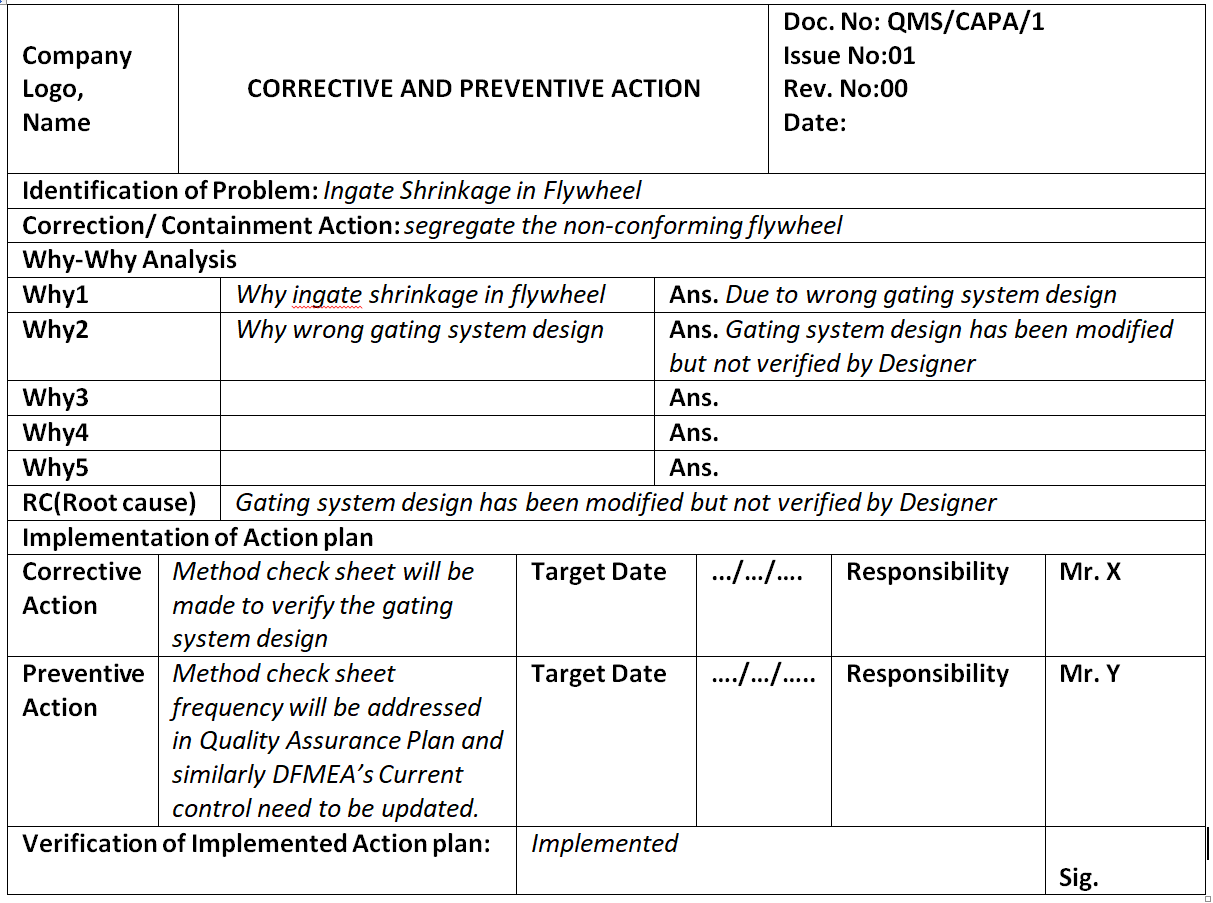

What Is a Corrective Action Plan? An effective corrective action plan identifies the root cause of problems and prevents their recurrence with rigorous documentation. The CAP aims to resolve the root cause of the issue rather than just address the surface signs. A corrective action plan template can help mitigate similar issues in the future.

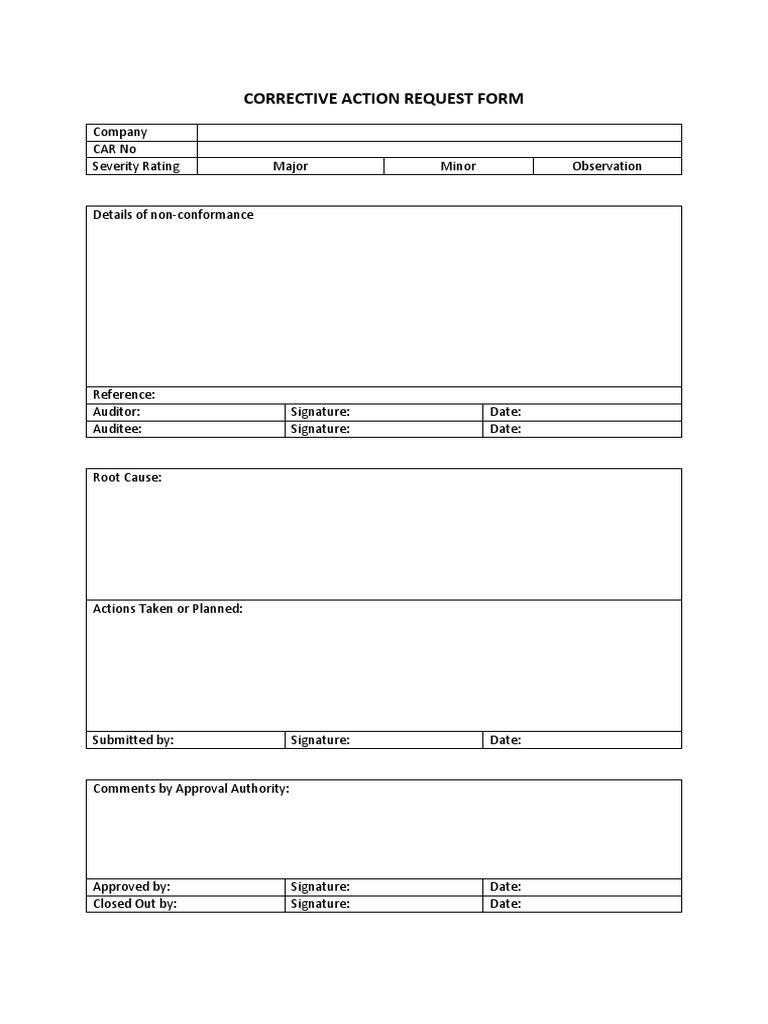

Top Corrective Action Request Form Templates free to download in PDF format

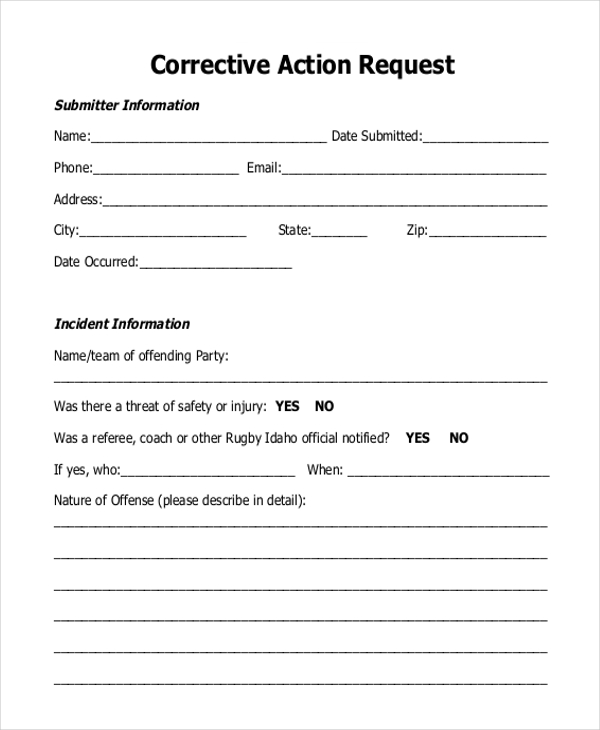

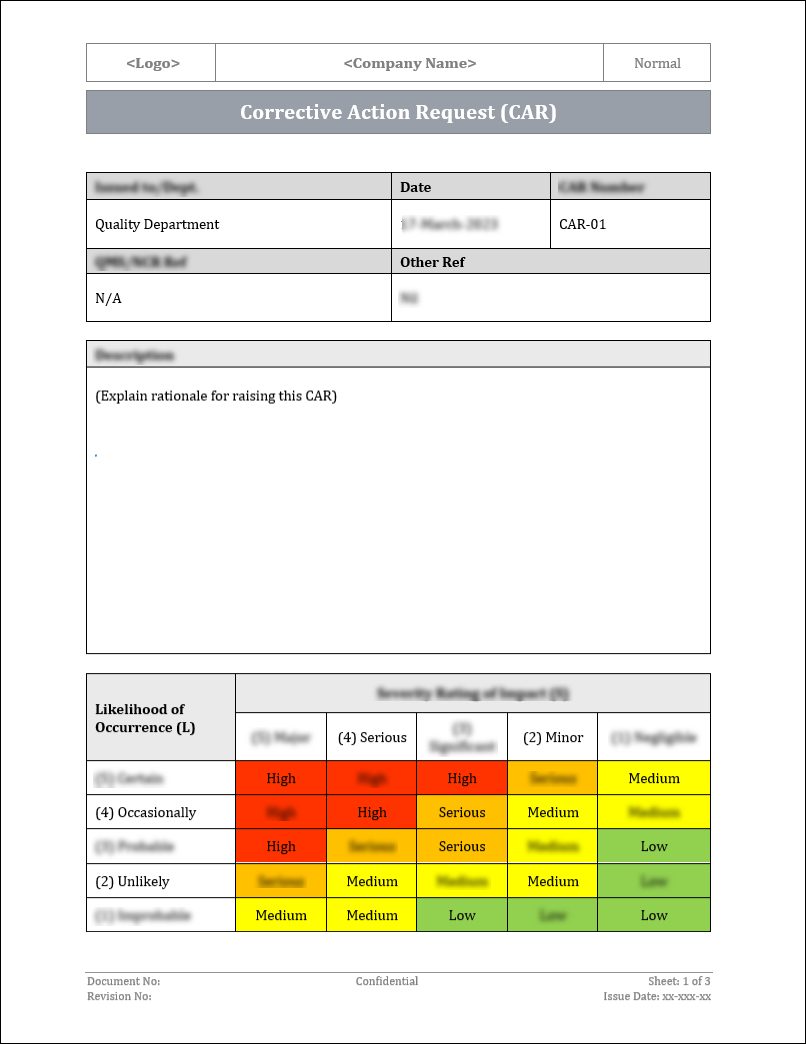

What is a Corrective Action Request? A corrective action request is a formal notification sent to the supplier for rectifications to be done on a nonconforming item, process, or service. Suppliers respond to a corrective action request to report the root cause of a nonconformity and the applied corrective actions to prevent recurrence.

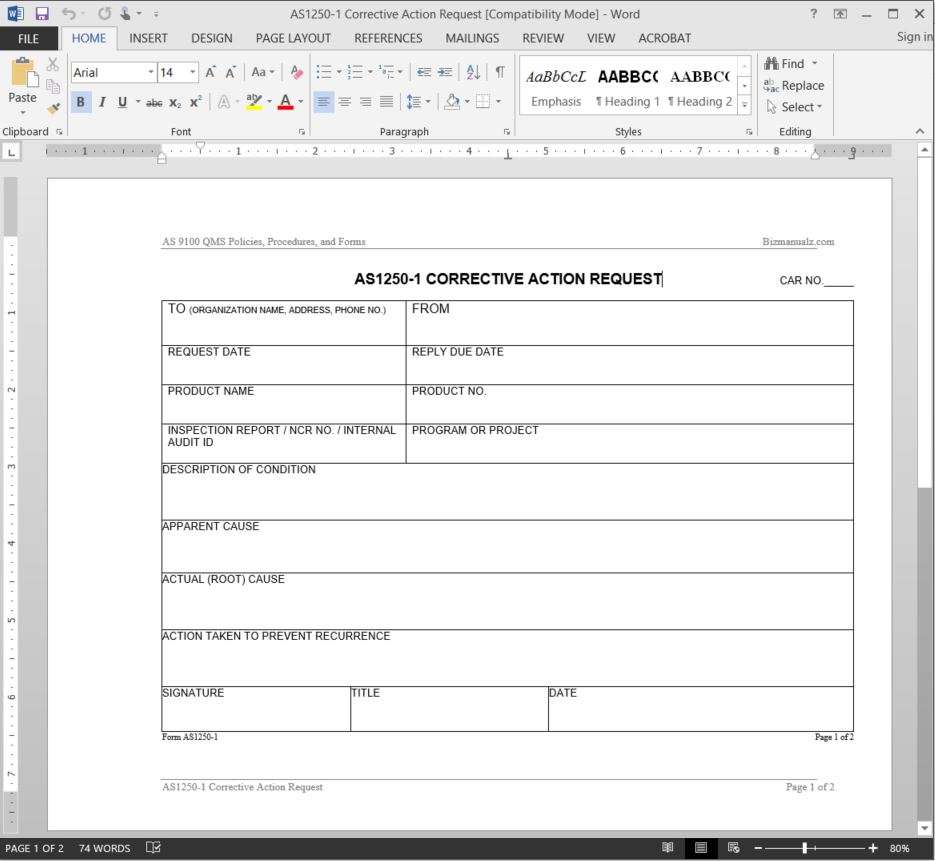

FREE 10+ Sample Corrective Action Forms in PDF MS Word Excel

A Corrective Action Request (CAR) is commonly defined as, "A formal notification sent to a supplier, where an item or process is in nonconformity and a remedy is required.". CAR's ask that the cause of nonconformities of a product, process, or service be eliminated, with the objective of preventing recurrence and are normally determined.

Sample_Corrective Action Request Form Business Process Management Business Process

Preventive action is taken to fix the cause of a process problem before it can happen. In a management system, a preventive action (PA) definition could be: "the activities taken by the organization to eliminate the cause of a potential process nonconformity.". If you are identifying potential problems that could happen in a process.

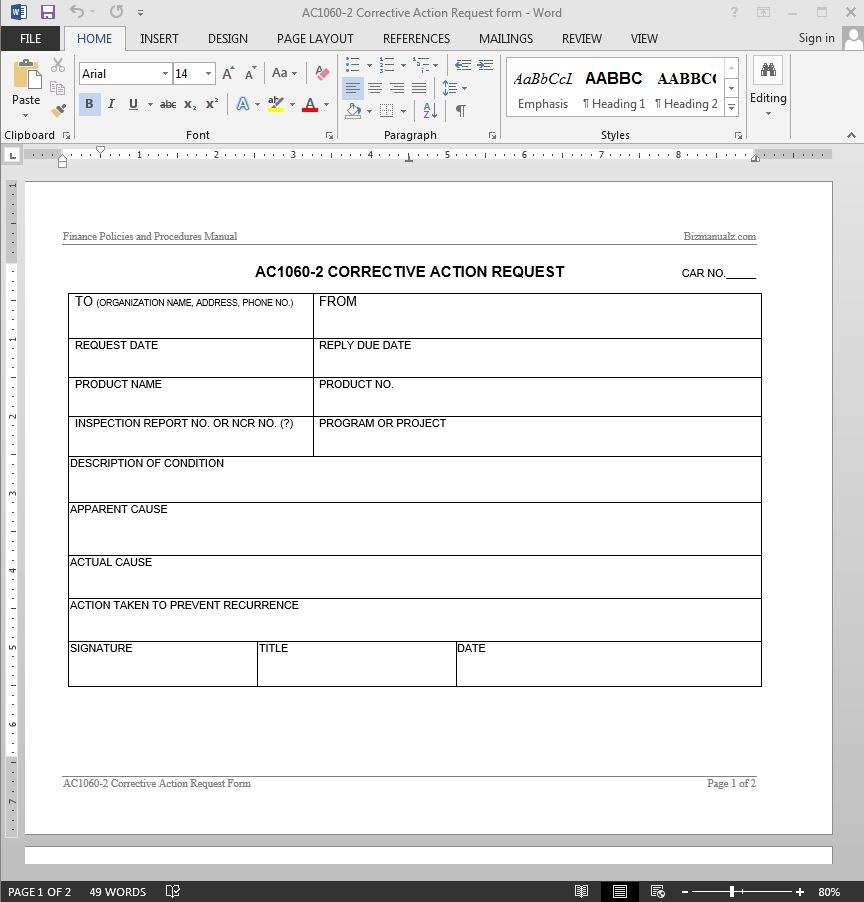

Corrective Action Request Form

If your supplier isn't delivering acceptable quality components, that affects your overall production schedule and ability to deliver the finished device on time. This White Paper provides a discussion on managing the Supplier Corrective Action Request (SCAR) process effectively, and in accordance with requirements per 21 CFR 820.50 and ISO.

11+ Corrective Action Plan Examples in Word Examples

A corrective action request (CAR) is a formal change request regarding a nonconformity issue within an organization. These generally occur following an audit of a quality management system (QMS), with the CAR used as a method for notification of the nonconformity and documentation of the action used to correct it.

Printable Corrective Action Plan Template Customize and Print

A corrective action request is a formal request to cease the cause of a nonconformity in an item, process, or service. A detailed corrective action request can include different levels of concern based on the nature of the issue. A CAR can originate with a customer complaint, an audit or inspection, or a production line event.

Corrective Action Request

Corrective action uncovers and prevents systemic quality issues. From time to time, every business experiences defects (AKA non-conformances) in their end product or procedures. Some are major, such as a product failing a safety check when it rolls off the production line. Others are minor, such as cosmetic flaws in the finish of a single.

Understanding Corrective Action Request Stepbystep guide

Although CAR stands for Corrective Action Request, most companies use CAR to mean the entire process. That's okay as long as we all use the same interpretation.] During the investigation a root cause is discovered as to why operators are stumbling. It seems there is unevenness in the floor and an obstruction that, if removed, should eliminate.

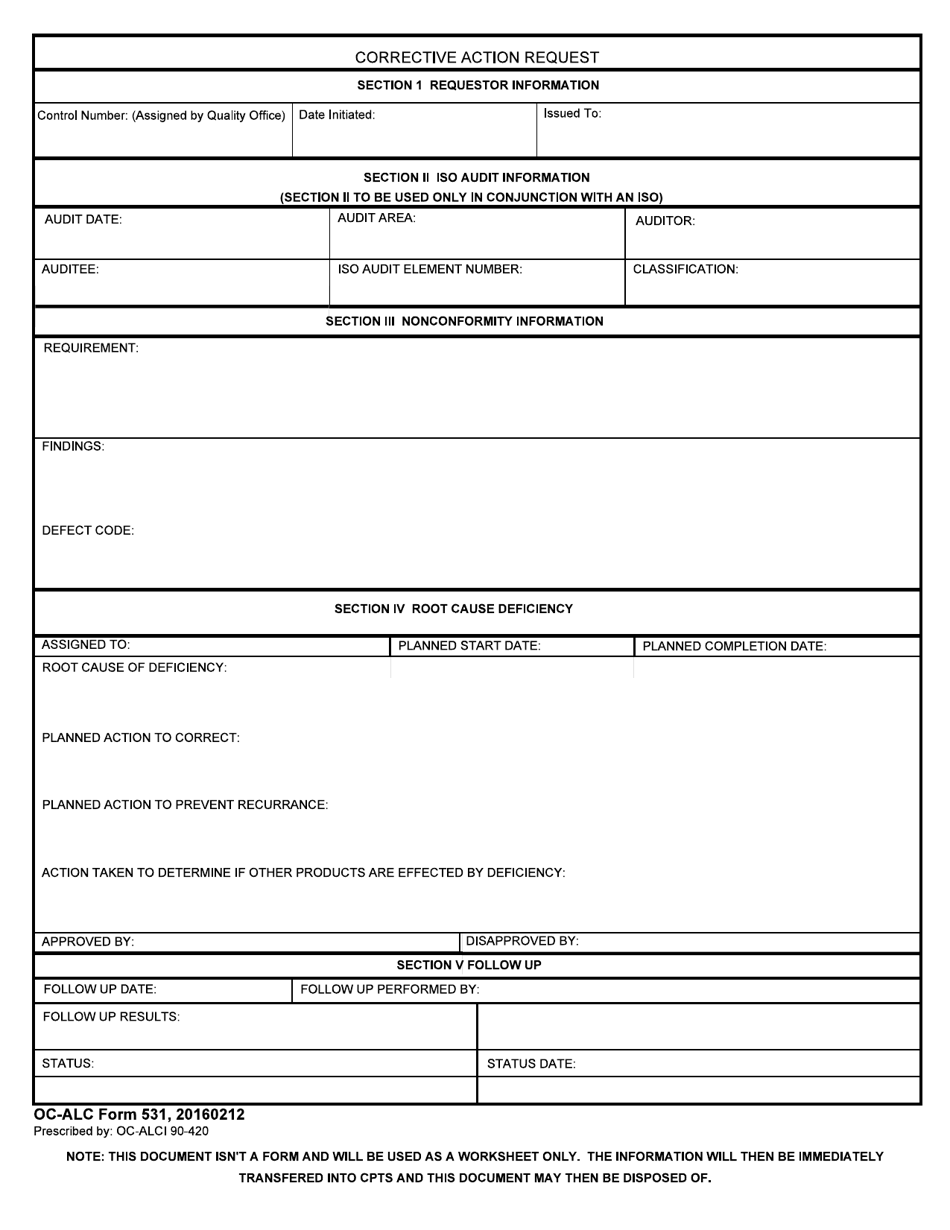

OCALC Form 531 Fill Out, Sign Online and Download Printable PDF Templateroller

Corrective Action Request Definition. A corrective action request (CAR) is a type of change request that documents a problem with a product or process and requests the root cause of a nonconformity be removed.

Missouri Corrective Action Request (Car) Fill Out, Sign Online and Download PDF Templateroller

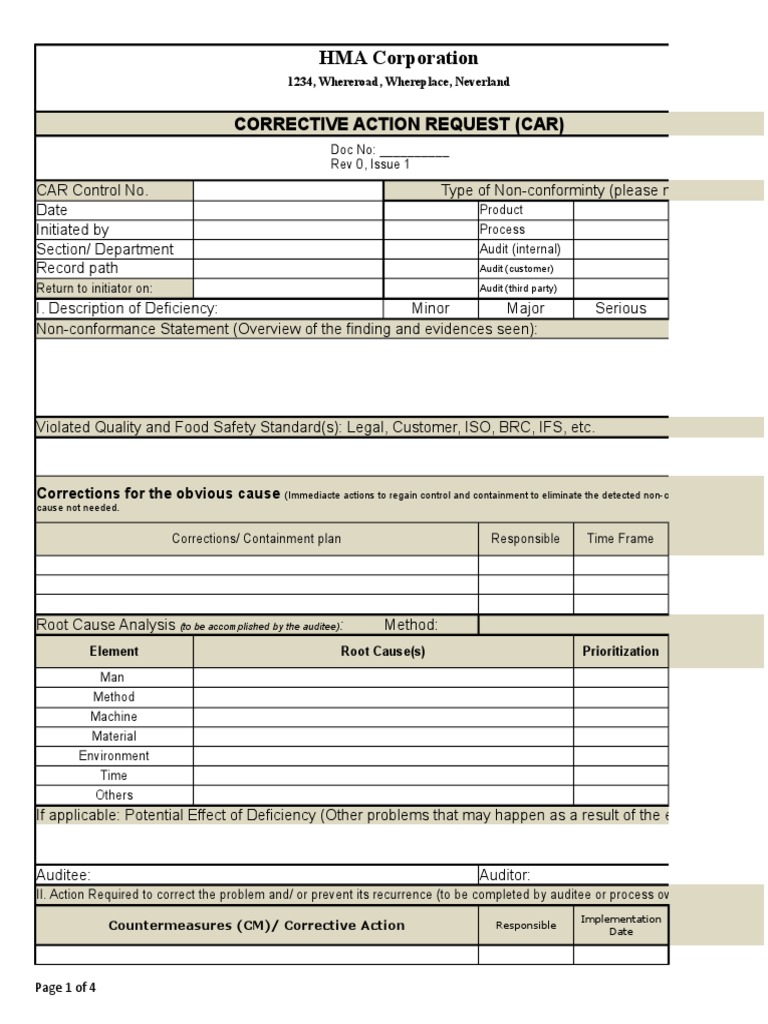

A supplier corrective action request, or SCAR is a formal request given to a supplier that they correct a problem and explain to you exactly how they will do so. The problem may stem from a nonconformity related to the quality of its product or service. The requesting organization may also ask the supplier to follow an eight disciplines (8D.

Corrective and Preventive Action Format CAPA with Example

Root Cause Analysis in 5 steps. There are 5 steps for carrying out an RCA. 1. Recognize the problem. First, as a team there needs to be recognition that there is a problem. That should be obvious if you have received a CAR. The customer's review team will have identified that there is a problem, and have approached you to resolve it.

Corrective Action Response Form With Instructions Production And Manufacturing Business

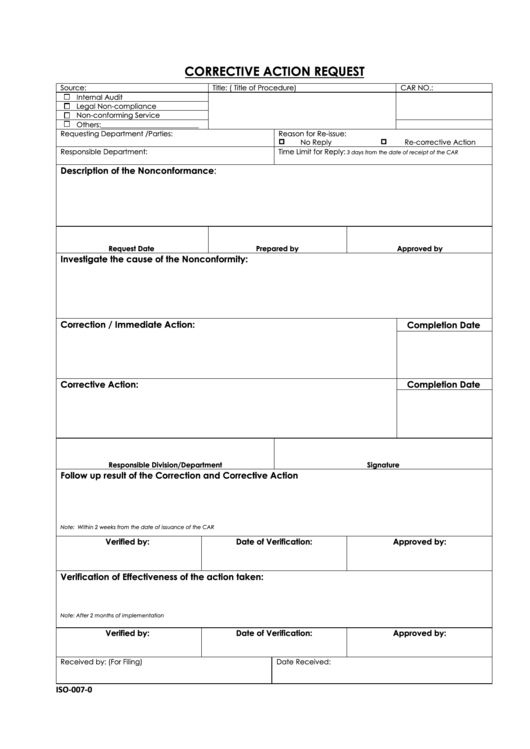

A corrective action request form should contain all the relevant and necessary information for resolving the issue. Here are some of the essential elements that should you should include in your template: Description of Nonconformity. The Corrective Action Request form should start with a clear and concise description of the nonconformity or.

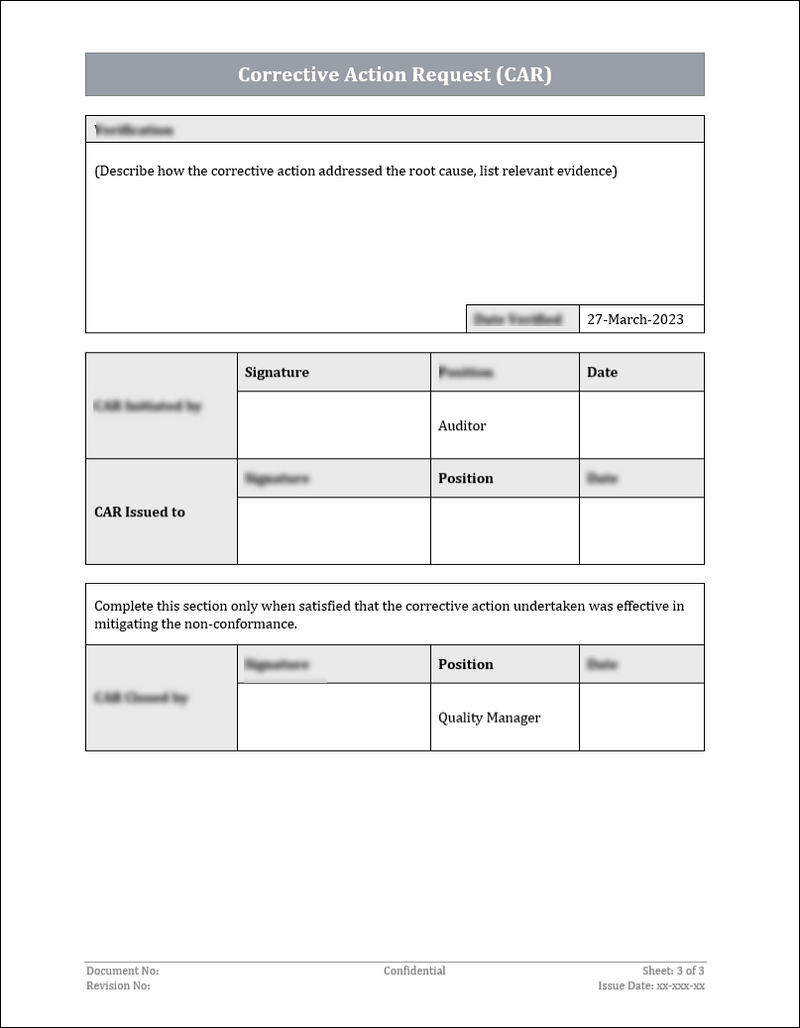

ISO 9001QMS Corrective Action Request Template ISO Templates and Documents Download

A corrective action plan is a documentation used in quality management that outlines a set of steps for addressing issues and gaps in business operations and processes that could negatively impact the business . It describes the approach for resolving an issue that interferes with reaching company goals. The corrective action plan should be S.M.

Corrective Action Request Template

A Corrective Action Request (CAR) is sent to a supplier where an item, goods, service, or process is in nonconformity, and a remedy is required. The notification requests the supplier to explain the reason for and proposed solution for a nonconformity discovered. CARs are normally determined during quality assurance activities.

Template Supplier Corrective Action Request PDF Computing Technology & Engineering

If you happen to receive a corrective action request, don't panic. The entire purpose of this system is to resolve issues with the least amount of consequences possible. However, you should go to great lengths to correct the issue and prove how you will prevent it from reoccurring in the future. It's vital to include certain information in.